Feature

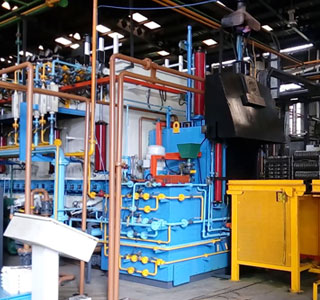

- Suitable for carburising, carbonitriding, normalising, annealing, case hardening with forced gas cooling/ oil quenching facility

- Available in gas fired and electrically heated versions

- Protective atmosphere can be Endothermic gas, Methanol + N2 or Rapid Carb [LPG + air (in-situ)]

- Supplementary washing machine with single chamber/ double chamber and tempering furnace

- Fully automatic with PLC and PC based data logging/ Scada software system/ O2 probe for furnace atmosphere control

- In/ out version for carburising/ annealing

- Straight through version for oil quenching

- Data acquisition system – PC based (optional)

- Available from 100 kg to 1200 kg gross loading capacity

- Furnace conformance according to API-6A norms

Atmosphere Gas

- Endothermic Gas

- Nitrogen + Methanol

- Drip Feed

- Direct Carburizing

Uses

- Carburizing, carbonitriding, bright annealing, re-carburizing, tempering etc.

| Specification | Effective Dimension (mm) | | | Max Operating Temp () | Power Requirement (Kw) | | Atmosphere Requirement | Heat Treating Capacity |

| Type | L | W | H | | Heating Chamber | Quench Oil Tank | Nm/Hr | Kg/Gross

|

| BCFE-S100 | 600 | 500 | 400 | 950 | 27 | 12 | 4 | 100 |

| BCFE-S400 | 955 | 510 | 455 | 950 | 40 | 18 | 8 | 400 |

| BCFE-S600 | 1230 | 660 | 600 | 950 | 80 | 24 | 14 | 600 |

| BCFE-S800 | 1230 | 750 | 660 | 950 | 100 | 36 | 18 | 800 |

| BCFE-S1000 | 1230 | 750 | 750 | 950 | 120 | 48 | 18 | 1000 |